SHENZHEN LONNMETER GROUP is a global intelligent instrument industry technology company. The group is headquartered in Shenzhen, China's science and technology innovation center. After more than ten years of steady development, it has formed a collection of research and development, production, sales and service. A group company of measurement, intelligent control, environmental monitoring and other series of project products.

Choose Lonnmeter for accurate and intelligent measurement!

Methanol Concentration Meter Inline

Working Principle

The inline methanol concentration monitor is excited by a piezoelectric tuning fork to vibrate at its natural frequency. The change of its frequency is measured when it's fully immersed in a fluid. Fluid density is in inversely proportion to frequency shift. The greater the density, the more mass the tines have to vibrate, and the lower their frequency becomes. Then an electronic circuit amplifies the detected signal and converts the physical signal to a density or concentration value.

Product Features

● Real-time density measurement for direct process control;

● Supports density-to-concentration conversion for all medium;

● High-precision 5-digit (4 decimal places) real-time readings;

● Converts measured density to 4-20mA or RS485 digital signal;

● On-site parameter setting and commissioning;

● Customizable wetted part materials for corrosive medium;

Interested? Contact Sales Team

Challenges in Inline Methanol Concentration Measurement

● Temperature and pressure changes alter methanol concentration;

● Sensor degradation over time caused by methanol with trace acids from hydrolysis;

● Fouling and deposition on sensor surfaces lead to slow response times or drift;

● Dynamic flow rates cause uneven medium contact;

● Bubbles in methanol stream reduce the effectiveness of density measuring;

Advantages of Lonnmeter Inline Methanol Concentration Meter

● -30~120 ℃ temperature compensation to minimize interferences from temperature changes;

● Customizable corrosion-resistant materials (Stainless steel, titanium alloy, Hastelloy alloy, PTFE, ceramic);

● Install and immerse on stable methanol stream;

● Simple mechanical structure minimizes possibilities of maintenance and replacement;

● Ultra-low error margin (±0.2% full scale);

● Automatic data logging and documentation;

More Applications? Consult Engineers Now

Parameter Selection Table

| Methanol Concentration Meter | Specification Code | Specifications | |||||

| Density Measurement Range | 1 | 0~1 . 5 g/cm³ | |||||

| 2 | 0~2 g/cm³ | ||||||

| X | Others | ||||||

| Process Connection | D1 | 2" 150LB Flange | |||||

| D2 | 2" 300LB Flange | ||||||

| D3 | DN50 PN25 Flange | ||||||

| D4 | DN50 PN40 Flange | ||||||

| K1 | 2" Clamp | ||||||

| K2 | 3" Clamp | ||||||

| M1 | G3/4 Thread | ||||||

| M2 | G1 Thread | ||||||

| XX | Others | ||||||

| Material of Wetted Parts | J1 | 316 | |||||

| J2 | Titanium | ||||||

| J3 | Zirconium | ||||||

| J4 | Hastelloy-C alloy | ||||||

| JX | Others | ||||||

| Surface Treatment | A | Standard Polishing | |||||

| B | Electropolishing | ||||||

| C | PFA Coating | ||||||

| Probe Length | 0 | Standard Length | |||||

| 1 | 100 mm | ||||||

| 2 | 200 mm | ||||||

| 3 | 300 mm | ||||||

| 4 | 400 mm | ||||||

| 5 | 500 mm | ||||||

| X | Others | ||||||

| Accessories | F0 | None | |||||

| F1 | Mounting Bracket | ||||||

| F2 | Bypass Pipeline | ||||||

| F3 | Flow Cell | ||||||

| F4 | Flushing Port | ||||||

| F5 | Flange Support | ||||||

| F6 | Protective Cover | ||||||

| FX | Others | ||||||

Customization Options

I. Core Performance Customization

II. Environment and Safety Customization

Installation

Inline Density Meter Installation Diagram

About Lonnmeter

Service Philosophy:

Every little thing for customers is a big thing for LONNMETER!

Business Philosophy:

Help customers succeed!

Group Values:

Customer first, pursuit of perfection, embrace change, dedicated cooperation, hard work, happy life.

Group Mission:

Make measurement intelligence more accurate!

Group Vision:

In the next 3-10 years, LONNMETER will create a new generation of smart instruments leader in China! In the next 10-20 years, let more people in the world use LONNMETER products and become the new generation leader of global smart instruments!

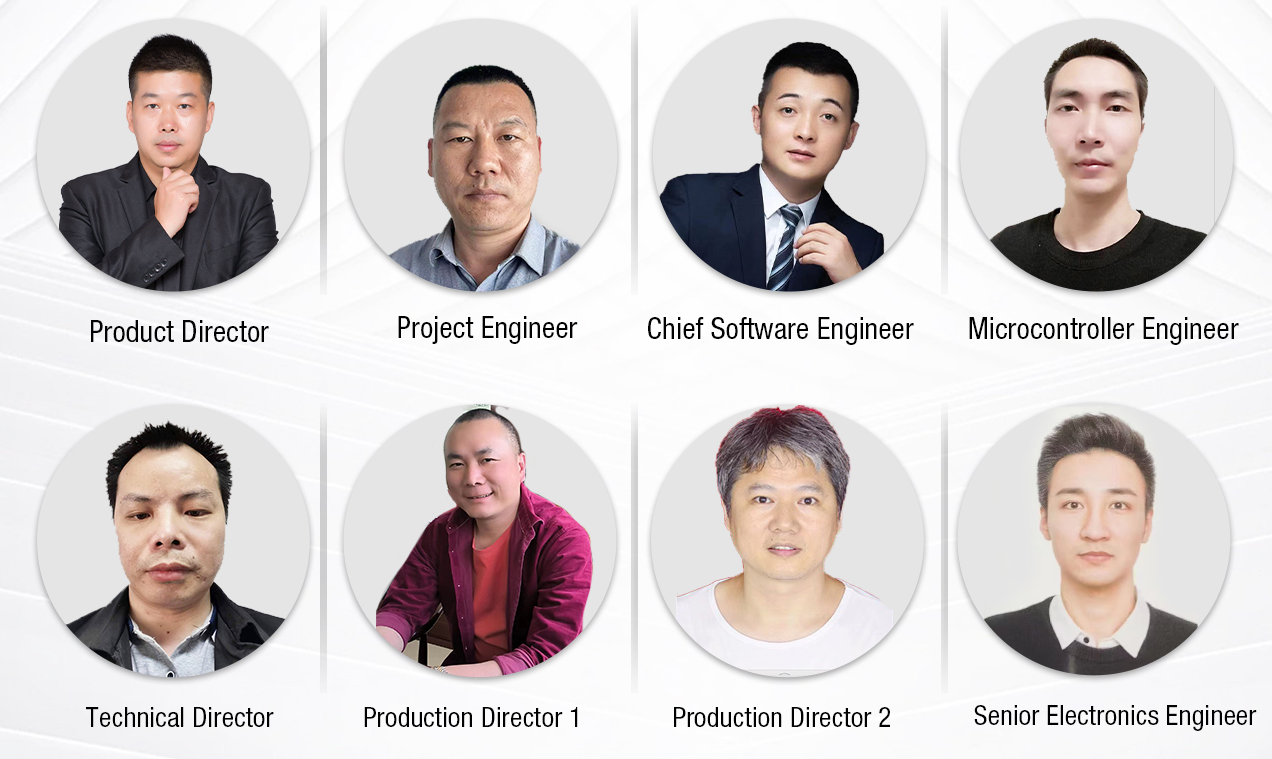

LONNMETER GROUP has seven professional production bases, more than 71 professional and technical personnel, and more than 440 skilled workers. The product quality is high, and the company has won many awards. At present, the company has obtained 37 national research and development patents, and its products have passed 19 international certifications such as CE, FCC, FDA, and TUV. The technical team of SHENZHEN LONNMETER GROUP is the core strength of the company. With its strong technical strength, it has conducted in-depth research and development on new products and new technologies in the intelligent instrument industry. The team worked hard to keep up with industry trends and made major breakthroughs in new product development.