SHENZHEN LONNMETER GROUP is a global intelligent instrument industry technology company. The group is headquartered in Shenzhen, China's science and technology innovation center. After more than ten years of steady development, it has formed a collection of research and development, production, sales and service. A group company of measurement, intelligent control, environmental monitoring and other series of project products.

Choose Lonnmeter for accurate and intelligent measurement!

Inline Paint Viscometer

It's also known as an inline ink viscosity meter or inline viscosity meter for ink for its outstanding performance in ink production lines. It's commonly installed in the supply line pipeline that carries ink from the main reservoir/tank/pump to the doctor blade chamber or the ink pan, providing immediate feedback on the ink viscosity just before it reaches the anilox roller or gravure cylinder. Looking into its working principle and see how it works in automated process control.

Working Principle

The inline paint viscosity meter consists of a sensor probe and a transmitter, designed for installation in reactors, reaction tanks, or pipelines to measure liquid viscosity in real time. It employs a solid rod-shaped sensing element that vibrates sinusoidally at a specific frequency, oscillating torsionally along its axis. The sensor features a single exposed element, enabling free fluid flow across its surface. As the element shears through the fluid, it experiences energy loss due to viscous drag forces, which vary with the fluid's viscosity resistance. This energy dissipation is detected by electronic circuitry and processed by the transmitter to generate a readable viscosity value.

Optional Material of Wetted Parts

316 L, Teflon, Hastelloy

Repeatability

±1% ~ 2%

Wide Viscosity Range

1 - 1,000,000 cP

Product Features

• Real-time continuous measurement enable immediate process adjustment to maintain consistent film thickness and color;

• Wide viscosity range handles low to high viscosities up to 1,000,000 cP;

• Built-in high-accuracy RTD sensor allows for automatic temperature compensation;

• High accuracy ±2% ~ 5% and repeatability ±1% ~ 2%;

• No-moving-parts design minimizes clogging, abrasion and maintenance;

• Robust and chemical resistant material stands up to corrosive solvents, pigments and cleaning chemicals;

• Threaded and flanged connections enable easy integration into pipeline, mixing tank or applicator feed line;

Benefits of Paint Viscometer

• Eliminates coating defects like runs and sags, orange peel or mottling, poor adhesion, etc.;

• Maintain tight viscosity control to ensure target film thickness;

• Real-time process control replaces time-consuming lab or efflux cup sampling;

• Increase throughput by keeping correct viscosity and lowering possibilities of re-work, scraping and repainting;

• Low-maintenance sensor reduce production downtime;

• Prevent over-thinning and over-addition of raw materials;

• Continuous monitoring make predictive maintenance possible;

OEM & ODM Service

• Viscosity range customization;

• Material Customization of wetted parts;

• Probe length customization

Contact our engineers right now if you need exclusive OEM and ODM service.

Parameter Selection Table

| LONN-ND | Specification Code | Inline Viscosity Meter | ||||||

| Probe Length (Optional) | L | Standard 220 mm | ||||||

| H | Extended 250-500 mm | |||||||

| F | Ultra-Extended for Reactor 550-1000 mm | |||||||

| Material | S | 316 | ||||||

| S1 | Teflon | |||||||

| S2 | Hastelloy | |||||||

| Temperature | P | 0-120℃ | ||||||

| G | 130-350℃ | |||||||

| Viscosity Measurement Range (Optional) | A | 1-50cp | ||||||

| B | 1-100cp | |||||||

| C | 10-1000 cp | |||||||

| D | 10-10000 cp | |||||||

| E | 100-100000cp | |||||||

| F | 1000-1000000cp | |||||||

| Output Signal | B | 4~20mADC + RS485 | ||||||

| Connection Method | F | Flange Connection | ||||||

| L | Threaded Connection | |||||||

| N | No Connection | |||||||

| Explosion-Proof Rating | D | EXd II BT6 | ||||||

| /B Protective Cover | ||||||||

| LONN-ND | L | S | P | A | B | F | D | /B |

About Lonnmeter

Service Philosophy:

Every little thing for customers is a big thing for LONNMETER!

Business Philosophy:

Help customers succeed!

Group Values:

Customer first, pursuit of perfection, embrace change, dedicated cooperation, hard work, happy life.

Group Mission:

Make measurement intelligence more accurate!

Group Vision:

In the next 3-10 years, LONNMETER will create a new generation of smart instruments leader in China! In the next 10-20 years, let more people in the world use LONNMETER products and become the new generation leader of global smart instruments!

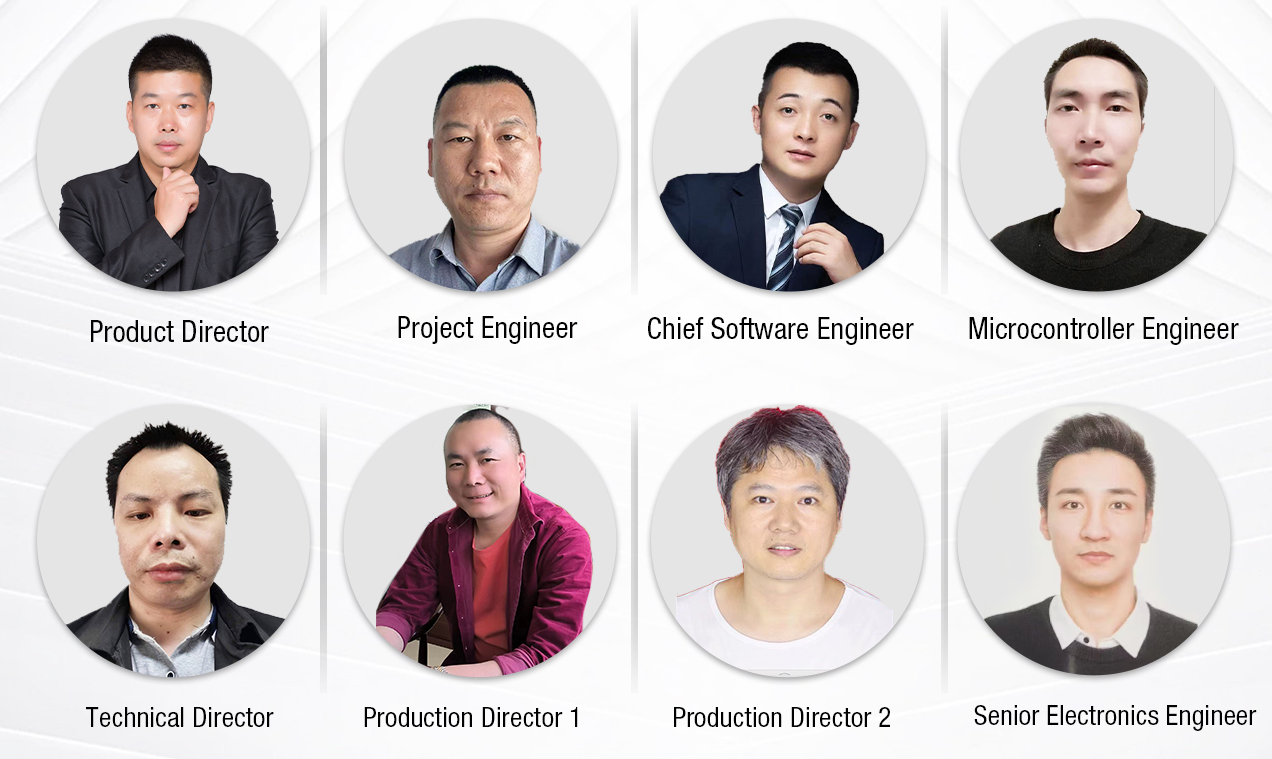

LONNMETER GROUP has seven professional production bases, more than 71 professional and technical personnel, and more than 440 skilled workers. The product quality is high, and the company has won many awards. At present, the company has obtained 37 national research and development patents, and its products have passed 19 international certifications such as CE, FCC, FDA, and TUV. The technical team of SHENZHEN LONNMETER GROUP is the core strength of the company. With its strong technical strength, it has conducted in-depth research and development on new products and new technologies in the intelligent instrument industry. The team worked hard to keep up with industry trends and made major breakthroughs in new product development.