SHENZHEN LONNMETER GROUP is a global intelligent instrument industry technology company. The group is headquartered in Shenzhen, China's science and technology innovation center. After more than ten years of steady development, it has formed a collection of research and development, production, sales and service. A group company of measurement, intelligent control, environmental monitoring and other series of project products.

Choose Lonnmeter for accurate and intelligent measurement!

Pipeline Density Meter

Density Meter in Pipeline

The pipeline density meter utilizes cutting-edge frequency tracking technology for compliance to high requirements in accuracy. It operates on vibration principle to excite a metal tuning fork by signal source of acoustic wave. Then the tuning fork vibrates at the central frequency, which is correlating to density and concentration in correspondence. Therefore, the liquid density could be measured, and temperature compensation can be applied to eliminate system temperature drift.

The concentration can then be calculated based on the relationship between the liquid density and concentration, providing the concentration value at 20°C. This pipeline densitometer is designed for insertion installation, offering a fully integrated "plug-and-play, maintenance-free" solution for density and concentration measurement. It is widely applicable for detecting medium density in pipelines, open tanks, and enclosed containers.

Highlights

Stable Output

4-20mA Output in a 4-Wire Transmitter

Real Time Accurate Measurement

current and temperature value display

Convenient Operation

direct settings & commissioning on site

Automatic Functions

fine-tuning and temperature compensation

Inline Real Time Measurement

real time readings for production process

Various Materials for Parts

safe and hygiene parts contacting with liquids

Applications

The density meter pipeline is applicable in petroleum, brewing, food, beverage, pharmaceutical and mining industry. Requirements of different medium varies in many industries. Please contact our engineer for detailed info and apply for a liquid density meter on trial.

Measurable Fluids in Common Fields

| Industries | Fluids |

| Chemicals | Nitric acid, phosphoric acid, acetic acid, chloroacetic acid, potassium hydroxide, sodium chloride, sodium sulfate, ammonium sulfate, ammonium hydrogen sulfate, ammonium chloride, urea, ferric chloride, urea, ammonia water, hydrogen peroxide |

| Organic Chemicals | Ethanol, methanol, ethylene, toluene, ethyl acetate, ethylene glycol, Tianna water |

| Petroleum | crude oil, gasoline, diesel, kerosene, silicone oil, lubricating oil |

| Pharmaceutical | pharmaceutical intermediates, solvents, polyvinyl alcohol, citric acid, lactic acid |

| Semiconductor | High-purity solvents, decontaminants, isopropyl alcohol, butyl acetate |

| Printing & Dyeing | NaOH, sodium carbonate, sodium bicarbonate |

| Equipment | Cutting fluid, emulsified oil, cutting oil, lubricating oil, antifreeze |

| Battery | Hydrochloric acid, sulfuric acid |

Parameter Selection Table

| Inline Pipeline Density Meter | Specification Code | Specifications | |||||

| Density Measurement Range | 1 | 0~1 . 5 g/cm³ | |||||

| 2 | 0~2 g/cm³ | ||||||

| X | Others | ||||||

| Process Connection | D1 | 2" 150LB Flange | |||||

| D2 | 2" 300LB Flange | ||||||

| D3 | DN50 PN25 Flange | ||||||

| D4 | DN50 PN40 Flange | ||||||

| K1 | 2" Clamp | ||||||

| K2 | 3" Clamp | ||||||

| M1 | G3/4 Thread | ||||||

| M2 | G1 Thread | ||||||

| XX | Others | ||||||

| Material of Wetted Parts | J1 | 316 | |||||

| J2 | Titanium | ||||||

| J3 | Zirconium | ||||||

| J4 | Hastelloy-C alloy | ||||||

| JX | Others | ||||||

| Surface Treatment | A | Standard Polishing | |||||

| B | Electropolishing | ||||||

| C | PFA Coating | ||||||

| Probe Length | 0 | Standard Length | |||||

| 1 | 100 mm | ||||||

| 2 | 200 mm | ||||||

| 3 | 300 mm | ||||||

| 4 | 400 mm | ||||||

| 5 | 500 mm | ||||||

| X | Others | ||||||

| Accessories | F0 | None | |||||

| F1 | Mounting Bracket | ||||||

| F2 | Bypass Pipeline | ||||||

| F3 | Flow Cell | ||||||

| F4 | Flushing Port | ||||||

| F5 | Flange Support | ||||||

| F6 | Protective Cover | ||||||

| FX | Others | ||||||

Installation

Inline Density Meter Installation Diagram

About Lonnmeter

Service Philosophy:

Every little thing for customers is a big thing for LONNMETER!

Business Philosophy:

Help customers succeed!

Group Values:

Customer first, pursuit of perfection, embrace change, dedicated cooperation, hard work, happy life.

Group Mission:

Make measurement intelligence more accurate!

Group Vision:

In the next 3-10 years, LONNMETER will create a new generation of smart instruments leader in China! In the next 10-20 years, let more people in the world use LONNMETER products and become the new generation leader of global smart instruments!

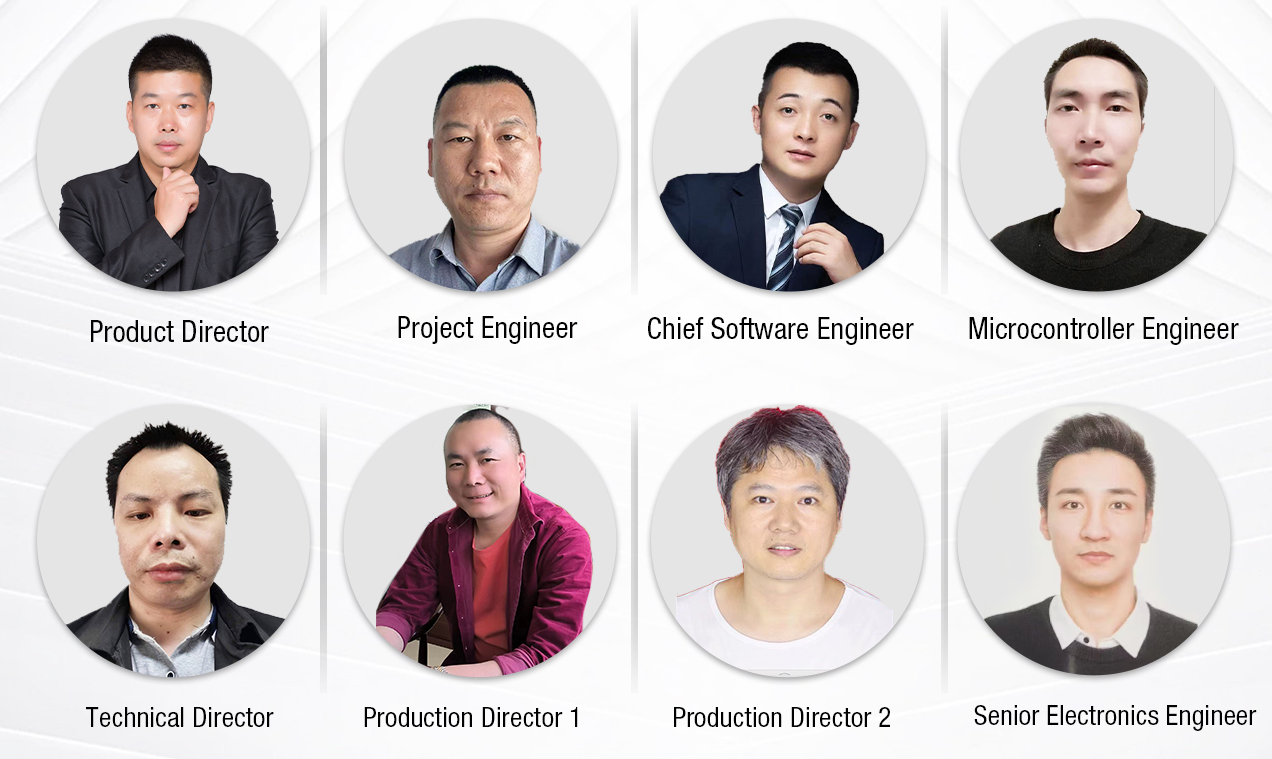

LONNMETER GROUP has seven professional production bases, more than 71 professional and technical personnel, and more than 440 skilled workers. The product quality is high, and the company has won many awards. At present, the company has obtained 37 national research and development patents, and its products have passed 19 international certifications such as CE, FCC, FDA, and TUV. The technical team of SHENZHEN LONNMETER GROUP is the core strength of the company. With its strong technical strength, it has conducted in-depth research and development on new products and new technologies in the intelligent instrument industry. The team worked hard to keep up with industry trends and made major breakthroughs in new product development.