SHENZHEN LONNMETER GROUP is a global intelligent instrument industry technology company. The group is headquartered in Shenzhen, China's science and technology innovation center. After more than ten years of steady development, it has formed a collection of research and development, production, sales and service. A group company of measurement, intelligent control, environmental monitoring and other series of project products.

Choose Lonnmeter for accurate and intelligent measurement!

Coriolis Density Concentration Meter

Coriolis Density Meter

Oil refining and blending of petrochemical industry are typical application of the Coriolis density meter. At the same time, it's an ideal option for viscous fluids like vegetable oil and beverages containing sugar. Fine chemical engineering often take the good advantages of inline concentration meter for accurate liquid measurement, such as weak acid- or alkali-based solution contacting with anti-corrosion parts directly. It also works in industries like paper manufacturing, wine production, salt processing, printing and dyeing.

Compared to similar inline density meters, it outperforms than others in viscous fluid measurement, especially in dirty or adverse working environments. It's maintenance-free and integrated into pipelines to provide continuous density and concentration monitoring.

Highlights

Integrated plug-and-play design

Continuous density monitoring

No moving parts and less maintenance

Customizable material of parts contacting with fluids (316L or titanium)

Feature built-in temperature sensor

Attentions

◮Applicable to places without shock and vibration;

◮No frozen mediums for fear of sensor damage;

◮Avoid direct contact with corrosive medium;

◮Prevent slag from accumulating in the tank;

◮Do violent throwing or knocking;

◮Do not measure highly corrosive liquids;

◮Do not exceed nominal pressure in operation;

◮Ban pipeline welding when installing the density meter.

About Lonnmeter

Service Philosophy:

Every little thing for customers is a big thing for LONNMETER!

Business Philosophy:

Help customers succeed!

Group Values:

Customer first, pursuit of perfection, embrace change, dedicated cooperation, hard work, happy life.

Group Mission:

Make measurement intelligence more accurate!

Group Vision:

In the next 3-10 years, LONNMETER will create a new generation of smart instruments leader in China! In the next 10-20 years, let more people in the world use LONNMETER products and become the new generation leader of global smart instruments!

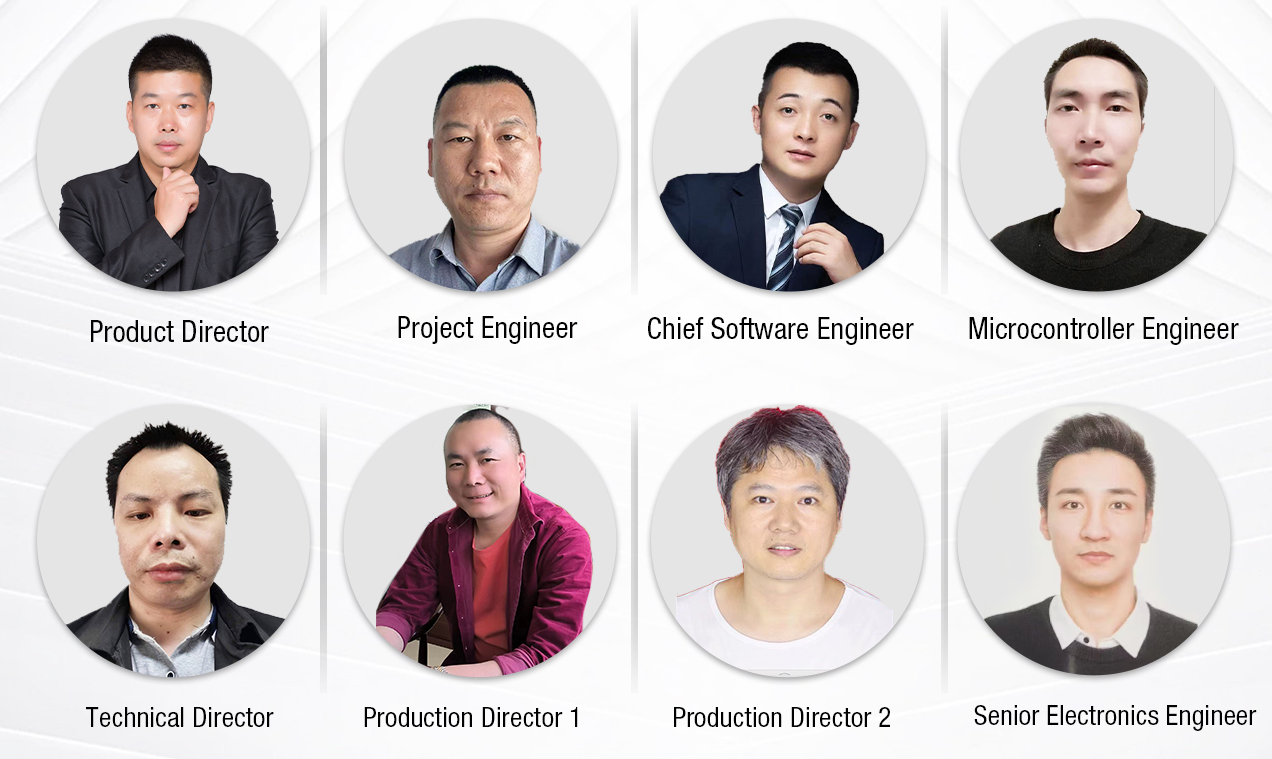

LONNMETER GROUP has seven professional production bases, more than 71 professional and technical personnel, and more than 440 skilled workers. The product quality is high, and the company has won many awards. At present, the company has obtained 37 national research and development patents, and its products have passed 19 international certifications such as CE, FCC, FDA, and TUV. The technical team of SHENZHEN LONNMETER GROUP is the core strength of the company. With its strong technical strength, it has conducted in-depth research and development on new products and new technologies in the intelligent instrument industry. The team worked hard to keep up with industry trends and made major breakthroughs in new product development.