SHENZHEN LONNMETER GROUP is a global intelligent instrument industry technology company. The group is headquartered in Shenzhen, China's science and technology innovation center. After more than ten years of steady development, it has formed a collection of research and development, production, sales and service. A group company of measurement, intelligent control, environmental monitoring and other series of project products.

Choose Lonnmeter for accurate and intelligent measurement!

Coolant Concentration Meter Inline

In metal cutting, grinding, stamping and other processing procedures, the concentration of coolants (such as cutting fluids, emulsions, oil - based coolants) directly affects lubrication, cooling, rust - prevention and chip removal effects, serving as a core parameter to ensure processing quality and equipment safety. The inline coolant concentration meter is equipped with a coolant concentration sensor resistant to the corrosion of various coolants. As a crucial inline process instrument, it enables real - time and accurate monitoring of coolant concentration. Its advantages of easy operation, high precision and efficient performance make it an ideal inline tool in multiple industrial applications.

Product Features

Working Principle

Product Advantages

Application

Some industrial plants or manufacturing facilities could benefit from the inline coolant concentration meter:

● Metal processing factories for cutting and grinding processes to monitor the concentration of emulsion in cutting fluids, ensuring stable lubrication, cooling and rust - prevention performance and reducing tool wear;

● Automobile manufacturing plants for engine and transmission processing lines to keep the coolant concentration within the optimal range, protecting components from overheating or corrosion during processing and testing;

● Industrial refrigeration plants for glycol cooling systems to monitor the continuous concentration of glycol solution, balancing antifreeze effect and heat transfer efficiency and preventing pipeline freezing or energy waste;

● Chemical production plants for reactor cooling circuits to maintain the stable concentration of cooling fluids, ensuring precise temperature control during chemical reactions and improving product quality stability;

● Shipbuilding yards for marine engine cooling systems to monitor the concentration of ethylene glycol and corrosion inhibitors in coolants, protecting engines from freezing in low - temperature navigation and reducing seawater corrosion.

More Applications? Consult Engineers Now

Parameter Selection Table

| Coolant Concentration Meter | Specification Code | Specifications | |||||

| Density Measurement Range | 1 | 0~1 . 5 g/cm³ | |||||

| 2 | 0~2 g/cm³ | ||||||

| X | Others | ||||||

| Process Connection | D1 | 2" 150LB Flange | |||||

| D2 | 2" 300LB Flange | ||||||

| D3 | DN50 PN25 Flange | ||||||

| D4 | DN50 PN40 Flange | ||||||

| K1 | 2" Clamp | ||||||

| K2 | 3" Clamp | ||||||

| M1 | G3/4 Thread | ||||||

| M2 | G1 Thread | ||||||

| XX | Others | ||||||

| Material of Wetted Parts | J1 | 316 | |||||

| J2 | Titanium | ||||||

| J3 | Zirconium | ||||||

| J4 | Hastelloy-C alloy | ||||||

| JX | Others | ||||||

| Surface Treatment | A | Standard Polishing | |||||

| B | Electropolishing | ||||||

| C | PFA Coating | ||||||

| Probe Length | 0 | Standard Length | |||||

| 1 | 100 mm | ||||||

| 2 | 200 mm | ||||||

| 3 | 300 mm | ||||||

| 4 | 400 mm | ||||||

| 5 | 500 mm | ||||||

| X | Others | ||||||

| Accessories | F0 | None | |||||

| F1 | Mounting Bracket | ||||||

| F2 | Bypass Pipeline | ||||||

| F3 | Flow Cell | ||||||

| F4 | Flushing Port | ||||||

| F5 | Flange Support | ||||||

| F6 | Protective Cover | ||||||

| FX | Others | ||||||

Customization Options

I. Core Performance Customization

II. Environment and Safety Customization

Installation

Inline Density Meter Installation Diagram

About Lonnmeter

Service Philosophy:

Every little thing for customers is a big thing for LONNMETER!

Business Philosophy:

Help customers succeed!

Group Values:

Customer first, pursuit of perfection, embrace change, dedicated cooperation, hard work, happy life.

Group Mission:

Make measurement intelligence more accurate!

Group Vision:

In the next 3-10 years, LONNMETER will create a new generation of smart instruments leader in China! In the next 10-20 years, let more people in the world use LONNMETER products and become the new generation leader of global smart instruments!

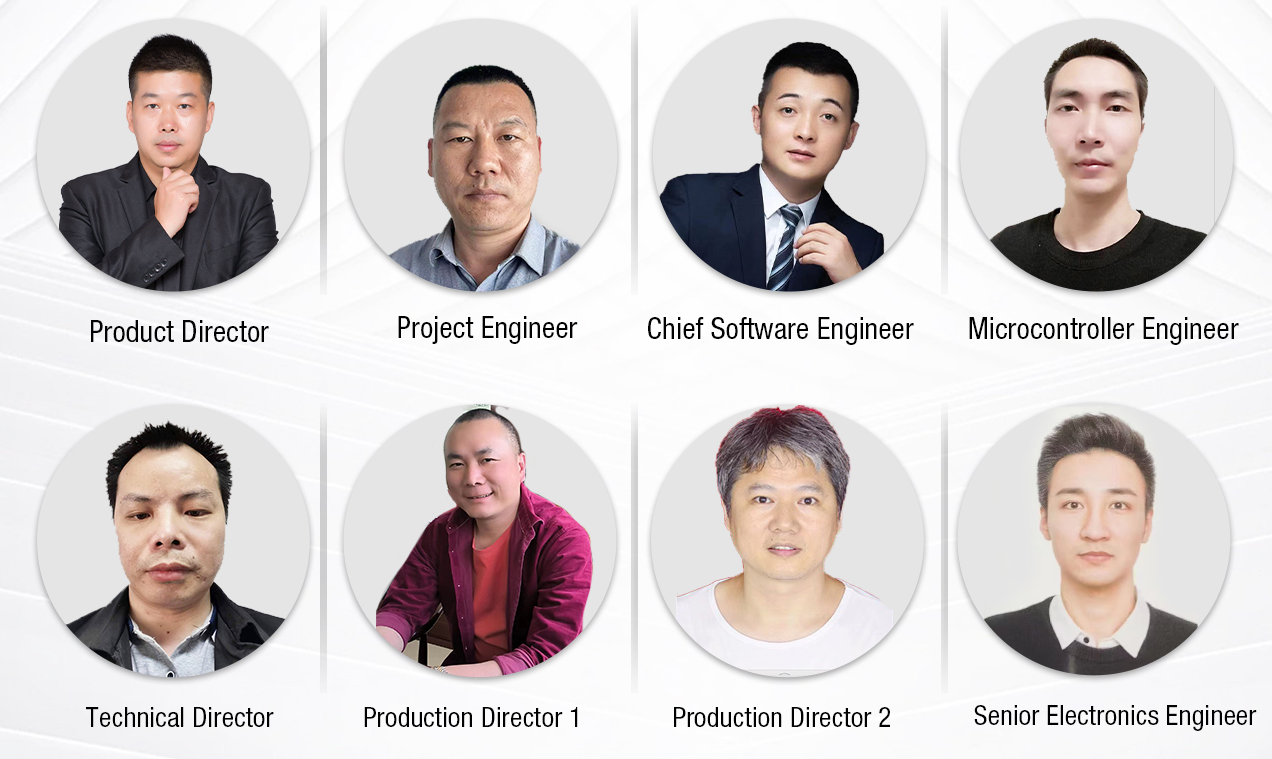

LONNMETER GROUP has seven professional production bases, more than 71 professional and technical personnel, and more than 440 skilled workers. The product quality is high, and the company has won many awards. At present, the company has obtained 37 national research and development patents, and its products have passed 19 international certifications such as CE, FCC, FDA, and TUV. The technical team of SHENZHEN LONNMETER GROUP is the core strength of the company. With its strong technical strength, it has conducted in-depth research and development on new products and new technologies in the intelligent instrument industry. The team worked hard to keep up with industry trends and made major breakthroughs in new product development.