SHENZHEN LONNMETER GROUP is a global intelligent instrument industry technology company. The group is headquartered in Shenzhen, China's science and technology innovation center. After more than ten years of steady development, it has formed a collection of research and development, production, sales and service. A group company of measurement, intelligent control, environmental monitoring and other series of project products.

Choose Lonnmeter for accurate and intelligent measurement!

Coffee Density Meter Inline

The inline caffeine concentration sensor contributes to flavor stability, waste reduction and scalable operations. It's particularly valuable for industrial-scale operations involving coffee extracts, concentrates, ready-to-drink (RTD) beverages, and brewing processes. Density measurements help optimize flavor, ensure standardization, and improve efficiency, often complementing or integrating with Brix/refractometry for comprehensive control.

Working Principle

It employs an acoustic signal source to excite a metal tuning fork, causing the fork to vibrate at its natural resonant frequency. Notably, this resonant frequency exhibits a direct correlation with the density of the liquid that the tuning fork contacts. Subsequently, the density of the liquid can be determined through frequency analysis—with temperature compensation implemented to counteract temperature drift within the system, ensuring measurement accuracy.

Product Features

● Enables real-time concentration or density measurement for direct product process control;

● Provides accurate, reliable 5-digit real-time readings (with 4 decimal places);

● Converts measured physical parameters into a standard 4-20mA current signal;

● Delivers real-time current and temperature readings;

● Allows direct on-site parameter setting and commissioning via simple menu access;

● Includes pure water calibration, fine-tuning, and temperature compensation functions;

● Offers selectable anti-corrosion materials for wetted components.

Applications

● Large-scale Coffee Breweries for coffee extract density measurement in hot/cold brew tanks, post-extraction pipelines and filling lines;

● RTD Coffee Production Plants for mixed coffee liquid density monitoring in ingredient blending tanks, homogenization lines and bottling lines to ensure stable flavor ratios;

● Instant Coffee Factories for coffee slurry density tracking in evaporation chambers, concentration tanks and spray drying feed lines;

● Coffee Concentrate Manufacturers for concentrate density control in dilution tanks, aging vessels and packaging lines to prevent over/under-concentration and meet customer-specified dilution ratios;

● High-Volume Specialty Coffee Cafés for espresso or batch cold brew density measurement in extraction lines and holding tanks;

● Flavored Coffee Drinks Plants for flavored coffee mixture density monitoring in syrup blending lines, dairy/non-dairy mixing tanks and filling lines to preserve flavor balance and consistent mouthfeel;

● Coffee Waste Recovery Facilities for residual coffee liquid density measurement in effluent pipelines and recovery tanks to identify high-value extract residues and optimize resource recycling.

Parameter Selection Table

| Inline Coffee Density Meter | Specification Code | Specifications | |||||

| Density Measurement Range | 1 | 0~1 . 5 g/cm³ | |||||

| 2 | 0~2 g/cm³ | ||||||

| X | Others | ||||||

| Process Connection | D1 | 2" 150LB Flange | |||||

| D2 | 2" 300LB Flange | ||||||

| D3 | DN50 PN25 Flange | ||||||

| D4 | DN50 PN40 Flange | ||||||

| K1 | 2" Clamp | ||||||

| K2 | 3" Clamp | ||||||

| M1 | G3/4 Thread | ||||||

| M2 | G1 Thread | ||||||

| XX | Others | ||||||

| Material of Wetted Parts | J1 | 316 | |||||

| J2 | Titanium | ||||||

| J3 | Zirconium | ||||||

| J4 | Hastelloy-C alloy | ||||||

| JX | Others | ||||||

| Surface Treatment | A | Standard Polishing | |||||

| B | Electropolishing | ||||||

| C | PFA Coating | ||||||

| Probe Length | 0 | Standard Length | |||||

| 1 | 100 mm | ||||||

| 2 | 200 mm | ||||||

| 3 | 300 mm | ||||||

| 4 | 400 mm | ||||||

| 5 | 500 mm | ||||||

| X | Others | ||||||

| Accessories | F0 | None | |||||

| F1 | Mounting Bracket | ||||||

| F2 | Bypass Pipeline | ||||||

| F3 | Flow Cell | ||||||

| F4 | Flushing Port | ||||||

| F5 | Flange Support | ||||||

| F6 | Protective Cover | ||||||

| FX | Others | ||||||

Installation

Inline Density Meter Installation Diagram

About Lonnmeter

Service Philosophy:

Every little thing for customers is a big thing for LONNMETER!

Business Philosophy:

Help customers succeed!

Group Values:

Customer first, pursuit of perfection, embrace change, dedicated cooperation, hard work, happy life.

Group Mission:

Make measurement intelligence more accurate!

Group Vision:

In the next 3-10 years, LONNMETER will create a new generation of smart instruments leader in China! In the next 10-20 years, let more people in the world use LONNMETER products and become the new generation leader of global smart instruments!

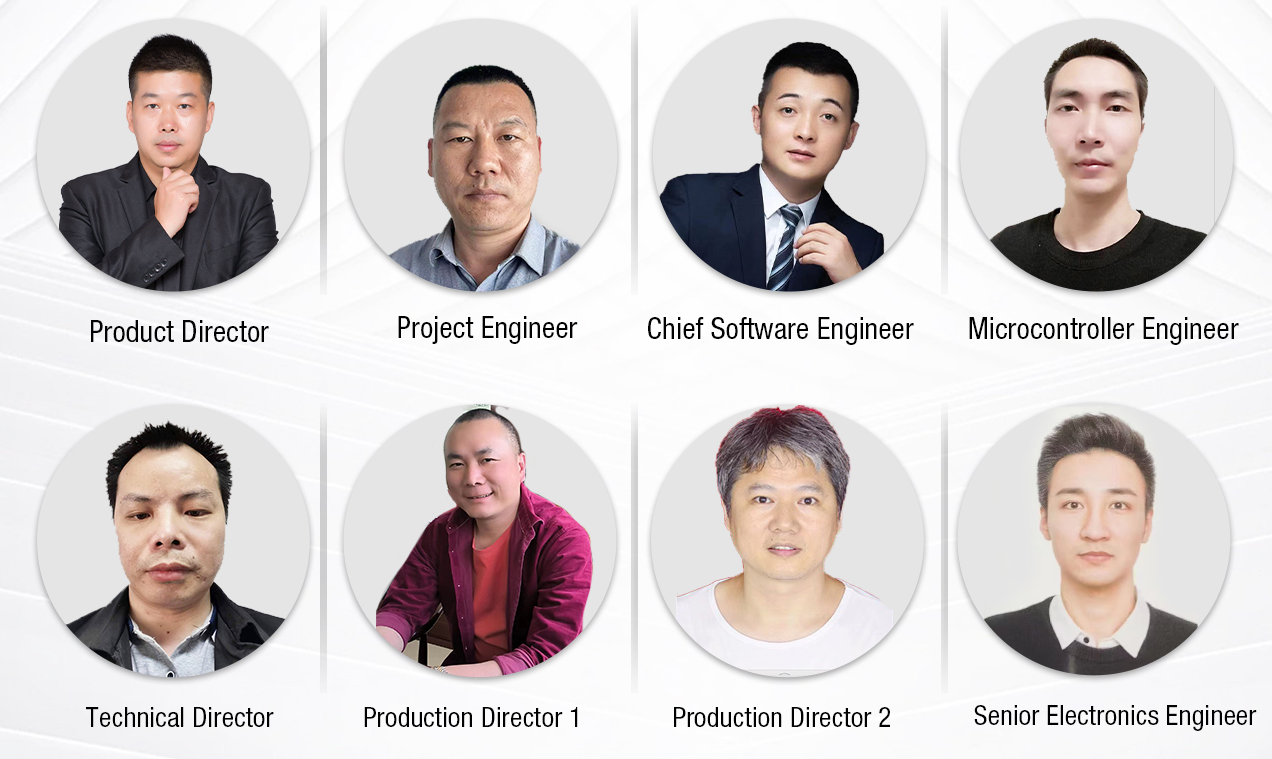

LONNMETER GROUP has seven professional production bases, more than 71 professional and technical personnel, and more than 440 skilled workers. The product quality is high, and the company has won many awards. At present, the company has obtained 37 national research and development patents, and its products have passed 19 international certifications such as CE, FCC, FDA, and TUV. The technical team of SHENZHEN LONNMETER GROUP is the core strength of the company. With its strong technical strength, it has conducted in-depth research and development on new products and new technologies in the intelligent instrument industry. The team worked hard to keep up with industry trends and made major breakthroughs in new product development.